Fixings and innovative solutions for pros at CELO

Injection mortar ResiFIX PYSF

The solid solution for non-cracked concrete

Product overview

Show more

The injection mortar ResiFIX PYSF is your ETA- approved solution for heavy-duty applications in non-cracked concrete (Option 7) and masonry (M8-M16) and many other base materials like aerated concrete, lightweight solid or hollow concrete blocks or sand lime bricks. Due to its high chemical resistance ResiFIX PYSF guarantees high loads and an installation free of expansion forces of e.g. anchor rods, anchor studs, square pipes, bolts and screws.

List of references

Filters

Content [ml]

Close

165

300

345

410

Packaging type.

Close

Cartridge

Carton

Reference

165PSF

300PSF

345PSF

410PYSF

Content [ml]

165

300

345

410

Material

Polyester

Polyester

Polyester

Polyester

Packaging units

1

1

1

1

Packaging type.

Cartridge

Cartridge

Carton

Cartridge

Applications

- Steel constructions

- Consoles

- Machines

- Guard rails

- Canopies

- Distance mountings

- Doors

- Wood constructions

- Facade substructures

Further specifications

Key features:

- ETA assessment option 7 expects at least 50 years of working life in non-cracked concrete

- ETA-Approval for masonry

- LEED tested - Sustainability certification for environmentally friendly, low-pollutant, low-emission and sustainable construction products

Base materials

Suitable materials with approvals

Concrete

Solid brick

Solid sand-lime brick

Lightweight solid concrete block

Hollow brick

Hollow sand-lime block

Hollow aerated concrete block

Aerated concrete

Other suitable materials

Natural stone

Other related products

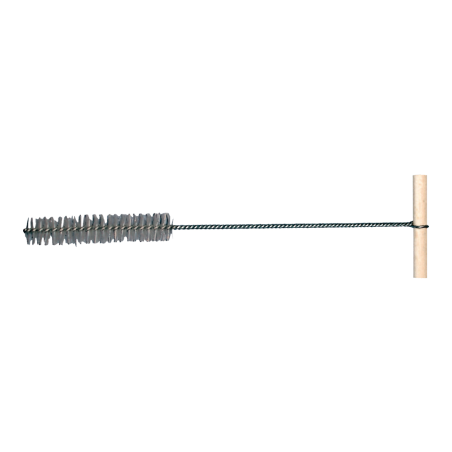

How to install

Mounting in concrete and solid brick

Mounting in hollow brick

Useful tips

Do you have any questions about this product?

Request more info